Cornelius Schmitt is either the Suge Knight or the Steve Jobs of sneakers. He’s borrowed from the image of the menacing hip-hop mogul, fashioning chains for himself and his team members inspired by those worn by Death Row associates. They bare the logo of Zellerfeld, Schmitt’s 3D-printed sneaker startup, and feature the text “Zeller Fella.” For women joining him on the mission of putting 3D-printed shoes on every foot on planet Earth, there is a “Zeller Bella” pendant. The correlation to Knight pretty much ends there for Schmitt, an exuberant German who in practice has much more in common with the other California titan.

Fashion designer Heron Preston, a Zellerfeld collaborator and source of inspiration for the company, likens Schmitt to a mad scientist. The first time they connected, via Zoom in 2020, he felt like he was talking to a young Steve Jobs. The space he operates out of looks something like a LAN party, Schmitt flanked by black towers of machinery.

“Meeting Cornelius was just like this genius, this brainiac who’s literally hand-building these printers with his buddies from college in a studio,” says Preston. “They don’t sleep—they never slept. I would just get messages from him any hour of the day, of the night.”

One gets the sense that if Schmitt is short on sleep, it’s because he is so overwhelmed with energy from the ideas he has—about how Zellerfeld can change the industry, about how its products can change the world. Plus, it allows him to maximize his hours spent actually using the 3D-printed sneakers.

“I wear them all the time,” he says of the shoes his slowly growing army of printers churn out, “I just take them off for sleeping.”

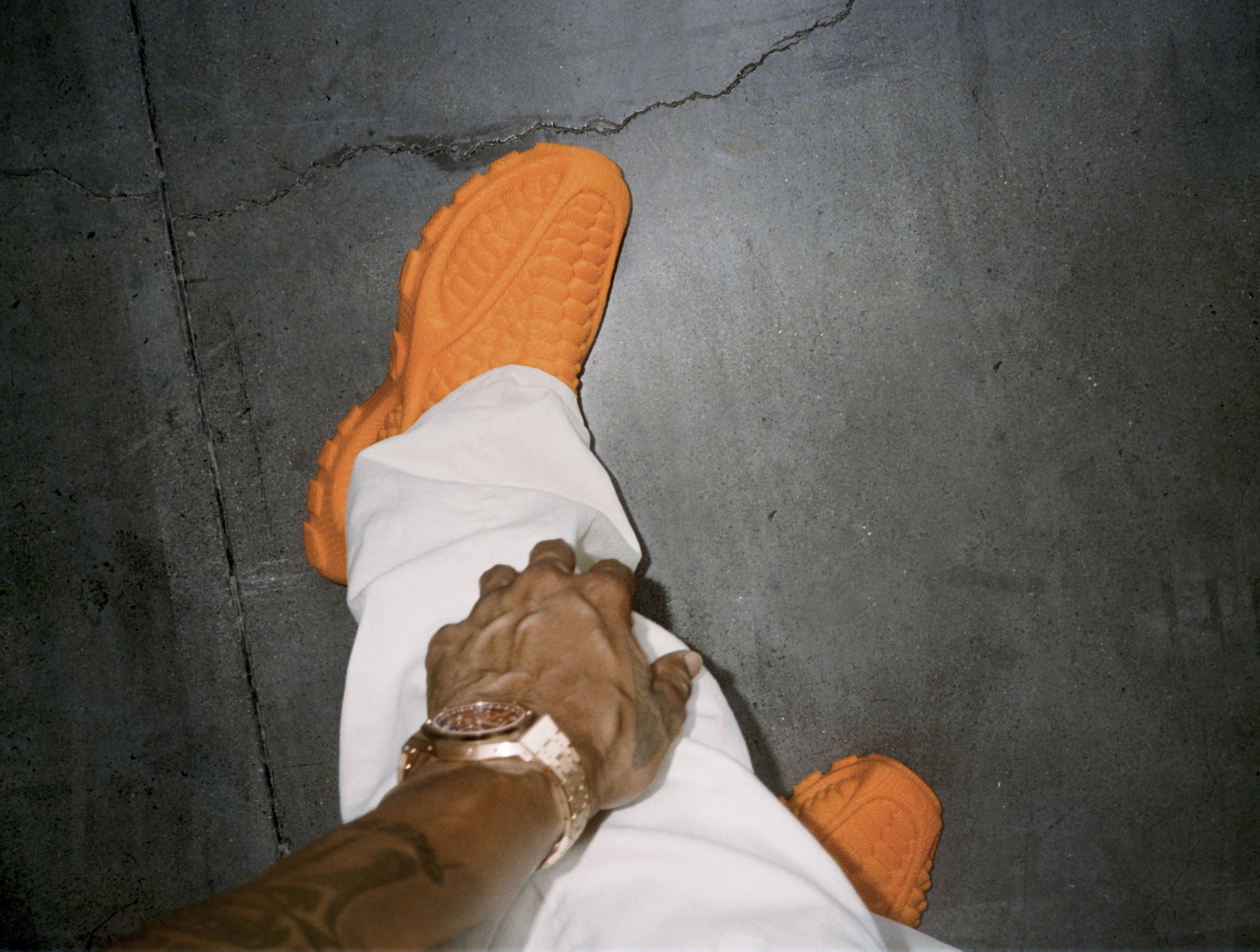

Zellerfeld shoes are squishy and springy to the touch, made entirely out of one material, a TPU polymer that feels like Adidas’ Boost material. They are designed by partners like Preston and Finn-Rush Taylor and produced by the company in limited quantities, for now. Preston’s, one of the first it’s sold, arrived via a StockX launch in October at $350 per pair. Their numbers are restrained by Zellerfeld’s manufacturing limitations, although the objective is to build a model that runs contrary to current hype machines that generate interest via exclusivity.

“There’ll be one day where these things are never sold out,” Preston says.

In one of the many futures Schmitt is eager to envision, that day is only a few years away. Though it currently takes Zellerfeld 40 hours to produce a single shoe, the company’s founder is working toward a timeframe where a collaborator could submit a digital file for a shoe to the printers and get a physical product to ship the same day.

His pace will quicken as he describes this to you, unraveling every possibility with increasing ardor as he gestures to the machines around him. It’s much easier to get him to start talking about all this than it is to get him to stop.

As of October, he’d cut manufacturing time in half by finding a more efficient way to program the 3D printer nozzles that spit out the layers comprising the shoes. Further along in the roadmap is a commercial facility in the US stocked with 3D printers that can spit out 5,000 sneakers in a day. His team is currently working on upping output by going from eight printers in the Hamburg warehouse where Zellerfeld is based to 200.

Zellerfeld, the company, is named after Zellerfeld the town, a burg of 15,000 in the German mountains where Schmitt studied engineering. His idea for a 3D-printed sneaker incubator was inspired in part by the total lack of cool shoes in the area. He started Zellerfeld in earnest between five and six years ago, hitting people on LinkedIn to help make it happen and soliciting advice from strangers with experience in the footwear industry. One of them was Gary Chwatuk, a professor at FIT who joined Zellerfeld as a creative director in 2019. He, along with Preston, helped refine the shapes of the shoes it made, taking them from pointy oddities to objects informed by actual design principles.

Is the goal to scale to a place where Zellerfeld could actually compete with sportswear powerhouses like Adidas or Nike? Not exactly. Many people at big sneaker brands have already made offers to invest in or buy the business, Schmitt says. He isn’t comfortable naming the would-be suitors (he did mention that Yeezy was calling three times a day at one point) but is clear that his company can’t exist alongside traditional sportswear makers.

“We very confidently said no to every time,” he says.

Schmitt is more fond of making comparisons to Tesla, which helps explain the shoes Zellerfeld made for Elon Musk and Grimes’ impossibly named child.

He wants sneaker design to work like open source software, and he wants the products to be patched like computer programs. Ideally, Zellerfeld shoes, like Preston’s, would be updated over the course of their life cycle—the creator could tweak the design, allowing the buyer to send their pair back to be recycled and remade into a 1.1 iteration of the same shoe.

The analogy Schmitt used for Zellerfeld’s potential when explaining the company to Preston was digital photography. Before the proliferation of digital cameras and phones with powerful cameras on them, taking, printing, and sharing photos was a more expensive and involved process. Zellerfeld wants to make footwear creation more digital and accessible.

The change is overdue. The sneaker industry is a tough one for designers to explore and make a name in if they don’t have connections to a billion-dollar brand with access to factories that make shoes. In streetwear, screenprinted tees and hoodies gave a generation a way to use their voice through apparel without needing too many resources or a co-sign from an established apparel company. A similar tool, one that can allow makers to easily turn ideas into reality sans corporate co-sign, doesn’t yet exist in sneakers. Once it does, the aperture of what’s possible will widen.

“I believe if experimentation is free and it’s not about the marketing departments planning 12 months ahead what consumers want, I believe through free experimentation much cooler shoes might emerge,” Schmitt says. “Shoes that no marketing department would bet on.”

His small company of 10 people doesn’t really have full departments just yet, let alone a phalanx of marketers determining what is and isn’t viable in the market. Preston says that the project right now is free of commercial pressure.

Schmitt has some idea of how he’d eventually make money, by charging artists and designers who want their shoes made a print fee. The profit in this scenario would be split between the creators, at 70 percent, and Zellerfeld, at 30 percent. But Schmitt also admits that even he isn’t certain what the business will eventually look like.

“We are running an experiment here,” he says. “We don’t know what the final business model will be. It might be like an AWS, where we just fulfill orders for brands and designers and customers don’t see us—might be. However, what we are currently testing is more like an app store model.”

Zellerfeld is still figuring out exactly what it wants to be. And the sneakers that it’s actually made are few. Aside from Preston’s, it’s produced concept car-style designs for brands like KidSuper, but none of its other shoes have come close to a retail release.

This beta stage of the company has involved 3D-printed versions of existing sneaker icons. According to Preston, he and Schmitt tried printing shoes like the Air Jordan 4 and the Nike Air Force 1 just to see how they’d look when rendered by Zellerfeld’s printers. The results felt anachronistic and inappropriate, says Preston.

“When you started to look at very vintage styles that were built around this lacing system,” he says, “when you start to kind of modernize them for 3D printing, they look kinda weird.”

There are pieces, panels, and materials from retro sneakers like the Jordan 4 and the Air Force 1—both sneakers from the ’80s—that don’t read right when etched out as a singular chunk of material. Zellerfeld’s monotone shoes that have been shown to the public so far can’t contain the same verve as the varied color stories injected into more traditional sneakers. But Schmitt says that’s coming. Along with more colorful shoes, he says Zellerfeld is working on creating multiple materials from one.

By treating the TPU that its sneakers are made of, the company can create the sense of different materials—glossy parts, mesh-like parts, stretchy sock sections. This could be key in helping Zellerfed make real performance shoes, which it’s currently lacking.

Schmitt does play tennis in a 3D-printed pair of Zellerfeld shoes but that’s due more to founder’s zeal than any measurable athletic benefits the sneakers provide the wearer. He’s not afraid to make another bold prediction here, though, about the athletes who will soon wear the shoes.

“I’m pretty confident actually that in like, a few years’ time people will win the Olympics in our shoes,” he says. “Because they will be customized to them.”

These custom shoes could be printed differently for every member on a team. The players on offense and defense would have sneakers finely tuned to satisfy their needs on the field. Their sizes would be personal to them and not summed up in a singular number, defined instead by a digital scan of their feet. (Zellerfeld already has an app that can do this, blasting 30,000 points of light at one’s feet to make a shoe tailored to them.) These hypothetical shoes could even be made by a kid with a laptop rather than a brand with billion-dollar budgets.

“If it was owned by bigger companies, they would have a different vision for it,” Schmitt says of Zellerfeld. “Our vision really is to be, in a sense, to be the manufacturing platform for everyone.”

He seems uncertain for now if he’s interested in merely disrupting traditional systems of footwear production or totally destroying them. Schmitt says he doesn’t want to render extinct sneakers like retro Jordans, which can continue to exist in the world he’s imagining through his company. They will be, he predicts, like the Porsche 911, a machine once technologically advanced and still aesthetically valuable, to his Tesla, the vehicle of the future.

In another version of his plan, 3D-printed sneakers like his are an evolutionary step forward that will push everything in the past into obsolescence. He likens this progression to the slow embrace of athletic footwear over traditional shoes that’s transpired in the past 40 years.

“The whole society, almost, switched to sneakers because they are more comfortable, let’s be honest,” Schmitt says. “I believe the same will happen now with custom shoes.”